RECONDITIONED UNITS AVAILABLE FOR IMMEDIATE DELIVERY VIEW STOCK

MARINE

We provide complete driveline solutions from supply and design through to installation, servicing, repair and spare parts to all aspects of the marine industry. Applications include workboats, fishing, wind farm maintenance, tugs, military and pleasure craft. We can supply and support solutions for standard and hybrid marine transmissions, control systems, steering, trim tabs to fixed pitch propulsion, CPP, vibration and sound control.

INDUSTRIAL & MINING

Experts in whole life support to equipment working in the most arduous environments including airfield maintenance, raw materials and mining, rock crushing, quarrying, building and construction, conveyor systems. From the simplest clutch or industrial gearbox installation to the more complicated hybrid driveline solution we deliver, drawing on our vast experience of working with carefully chosen component and spare parts suppliers.

OFF HIGHWAY

We are the experts in vehicle life extension, offering bumper-to-bumper diagnostics, servicing, repair and overhaul to a wide range of driveline systems. We are accredited Twin Disc and SIDES service providers and our engineer’s hold accreditation from Detroit Diesel, Godiva, Iveco, Volvo, Scania, Dosifer, Caterpillar. We offer life-extension solutions along with preventative care and emergency support.

ELECTRIC & HYBRID

Go Green! We have a range of electric outboards, inbounds, motors and hybrid drive systems that can be fitted to new vessels and as a retrofit package. Our motors deliver high torque and are very quiet in operation, providing emission-free, cost-effective commercial and leisure boating. To assist with funding your green propulsion, we work with future technology investors who can fund individual and fleet projects.

FAQ's

Where is my oil sensor on my Twin Disc Gearbox?

There is no oil sensor. Twin Disc gearboxes have both a temperature and pressure sensor. For checking oil levels, there is a dipstick; please refer to your owner’s manual, which you can obtain HERE.

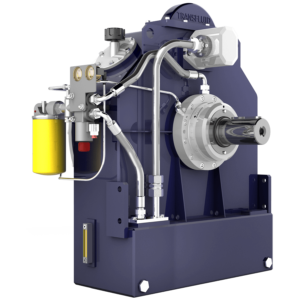

Why use Twin Disc MGX marine gears?

With the reliability that Twin Disc marine gears are renowned for, the MGX industrial gearbox offers both the durability and longevity of more traditional gears, along with providing instant clutch engagement and smooth slow speed control which provides users precise and safe handling of their vessel.

Paired with Twin Disc EC300 electronic controls the system offers unparalleled boat control in all conditions, while the revolutionary Twin Disc Dynamic Positioning System offers instantaneous, shock less and virtually constant forward and reverse shifting, keeping vessels on station.

To accomplish a faster and smoother clutch engagement, QuickShift utilises a sequenced engagement that operates automatically by design and does not need any adjustment. In the first stage of the engagement it makes up to 80% of the maximum oil pressure available to 20% of the clutch piston area, where conventional clutches have to get filled completely at four to five times lower pressure. This allows the clutch to fill much faster, thereby reducing the shift response time dramatically. Only then does a sequencing valve allow oil flow to the complete clutch piston area to fully engage the transmission.

The small difference between the already high torque transfer capabilities achieved at this stage to full torque provides for a very smooth and seamless engagement. Think how much more propulsion control that gives you. There’s never been anything like it. The patented Twin Disc QuickShift design offers in excess of 15 times faster clutch response and in excess of 10 times faster to full torque.

The Twin Disc QuickShift with its patented GP valve engages in 0.05 seconds, compared to a standard marine transmission’s 0.75 seconds, due to clutch fill time. QuickShift achieves full torque in 0.2 seconds, compared to a standard transmission requiring 2.0 seconds.

A Twin Disc QuickShift transmission with e-Troll has a clutch response after approximately 0.05 seconds, even when operating in trolling mode. This is in excess of 100 times faster than any conventional transmission with a conventional trolling valve.

Simply put, the QuickShift system shifts a lot faster than you do under any conditions.

Ok, so MIT Group, more than transmission parts! What services do you offer?

Aside from being the leading UK distributors for top brands such as Twin Disc, Transfluid, Rubber Design, Veth Propulsion and Quincy compressors, we have a dedicated and highly skilled team of engineers.

Our expert engineering team offer both planned and emergency driveline maintenance and repair, 24 hours a day, keeping your downtime to a minimum. Support is available both on-site and at one of our fully equipped northern or southern service centres.

Along with our industry-leading aftermarket support, we also offer TVA calculations, laser alignment, borescope inspection, assembly services and a fully bespoke driveline specification and installation service.

As part of our dedicated support to our customers, we also offer a service exchange program for when operational downtime is not an option. We also stock a vast array of spare industrial transmission parts, available, where possible on next day delivery.

How do I work out my vessels required power rating?

Twin Disc have conventionally complied a service classification guide, which can help you identify your duty cycle and required power rating. This can be found on page 26 of the Twin Disc Marine Product Guide brochure.

Our team of expert application engineers are on hand to identify the most suitable Twin Disc transmission for your vessel.

What about drive line alignment? Does it cause issues if not correctly done? How is it done?

Driveline alignment can cause major problems if not done correctly by exerting non-torque loads onto equipment in the system. Misalignment will cause premature failures of components in the drivetrain as well as exerting forces and vibrations into the supporting and surrounding structures which can lead to lower levels of operator comfort and fatigue in these structures. The severity of the issue and which component which will be affect will be different for specific driveline configurations.

Driveline alignments can be performed in a number of ways ranging from fully manual setups using Dial Indicators (DTI’s) and pointers to the more modern laser alignment. Laser alignment allows measurements to be taken much more quickly and accurately whilst automatically calculating the adjustments required at each mounting point. Some of the more complex laser alignment systems allow for the aligning of offset mounting flanges/shafts to ensure the drive and driven equipment are parallel to within the correct tolerance.

Once the initial measurement is taken the alignment is adjusted using traditional shims or levelling chocks. Shims are thin machined metal plates of varying thicknesses which are placed between the base and affixing machinery, these require that the machinery be lifted and reset every time an adjustment is made and depending on the size and weight of the machinery this can be an arduous task. Levelling chocks offer infinite adjustability within the height range by using 2 threaded components which lengthen or shorten with rotation and can be altered with machinery still in place. Levelling chocks have the secondary benefits of being able to accommodate discrepancies in machinery beds and taking up “soft foot”* through the bevel washer incorporated into the design.

I’m having marine gear issues, what should I check first?

We understand downtime to your vessel means a loss of revenue for your business. Before calling our expert repair team, below are some simple checks that can help get you back out on the water.

Check your oil level. Fill or drain to correct level with approved oil. Need help identifying your oil needs, call our team on +44 (0) 1795 580808.

Check the condition of your oil. Check colour and possible contamination or aeration.

Check your oil suction strainer to ensure the strainer is clean and free from blockages.

Check the control valve linkage (mechanical selection type) to ensure control valve stem is correctly indexing the detent.

Check gearbox oil pressures are correct to manufacturer’s specifications. Check in neutral and with clutch engaged.

If you have carried out the above checks and are still having issues, call our expert service team who are ready to assist.

Tell me more about the Quincy Air Compressor True Blue 5 year warranty.

Only the World’s Finest Compressors come with an industry leading warranty! Quincy Compressor offers 5-year coverage, surpassing competing models.

Other companies say they offer the best machine, but only Quincy can prove it. Quincy back their most reliable air compressors with an industry leading warranty.

- 5-year Airend Warranty

- 5-year Drive Motor

- 5-year Heat Exchanger

- 5-year Separator Tank

Talk to our team about all your compressed air needs.

What is MIT Off-Highway

EXTENDING THE LIFE OF OFF-HIGHWAY VEHICLES

Are your off-highway vehicles past their warranty period? Considering how you can ensure they remain cost-effective to your business? MIT has the answer!

We’re experts in providing bumper to bumper diagnostics, servicing, repair and overhaul to a wide range of driveline systems, including engines, torque converters, transmissions, axles, electronic systems, pumps and compressors, for an even more comprehensive range of Off-Highway Vehicles.

We are accredited Twin Disc and SIDES service providers and our engineer’s hold accreditation from Detroit Diesel, Godiva, Iveco, Volvo, Scania, Dosifer, Caterpillar. We are also an official ZF Service centre.

We offer life-extension solutions along with preventative care and emergency support.

Where can I find my Twin Disc gearbox manual?

You can obtain your manual by clicking HERE